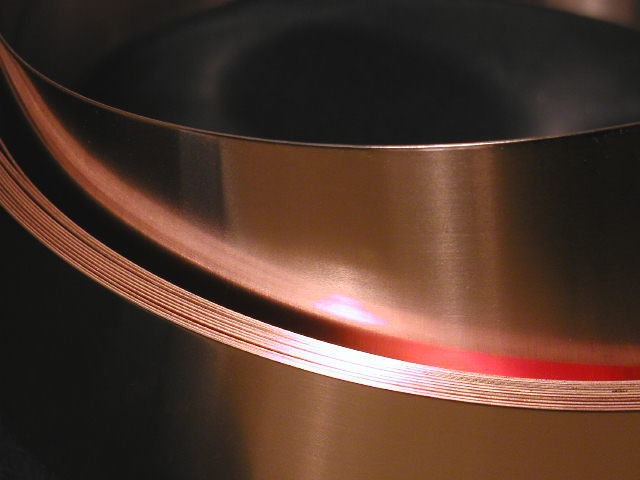

Copper Strap as a Conductor

Through the years, copper strap has earned its place in radio frequency applications. Visit any broadcast transmitter facility, and you’ll find copper strap used everywhere – around the base of towers, along the ground, underground, inside transmitter buildings, and even inside the transmitters themselves.

But why strap instead of wire? 1 AWG copper wire and a 3-inch x .022-inch copper strap each contain about the same amount of copper. The 1 AWG wire has a diameter of 0.289 inches, so its circumference is 0.91 inches. Multiply that by 12 inches, and you’ll find that one foot of this wire has a surface area of about 10.9 square inches. Flatten that same amount of copper into a strap 3 inches wide and .022 inches thick, and a 12-inch length has about 72 square inches of surface area. That’s over six times the surface area!

So, what’s the big deal about surface area anyway? Radio frequency currents flow mainly along the surface of a conductor rather than through the middle. So, conductors with a greater surface area can carry high-frequency current more efficiently, with a lower impedance, than conductors with less surface area. Sometimes, the copper strap is buried underground as part of a ground system. In this situation, there’s yet another benefit. The extra surface area provides more contact with the soil, further enhancing the ground system.

Many kinds of electrical conductors connect our world. Like you and me, they all have their place.